Arachnid Archery Part 2

In this post I am going to outline my opinion and experience with the actual Arachnid Archery product. Make sure you check out Part 1: The Buying Experience here.

Recap and Update on the Shipping and Cost

Before I go into the details of the arrows themselves I want to update on the final cost and delivery. I finally received these arrows on July 13,2021 after placing the order on June 18th, 2021. So the product took almost a full month to arrive, and when it did I was missing half the order. I reached out to Blake (the owner) via email and he responded that the other arrows would be sent out ASAP. After 3 days I contacted him again to get tracking information for the remaining arrows and was told it would be another 2-3 weeks before they had more stock. I asked for a refund on the second dozen arrows which he promptly applied.

Onto the cost, after crunching the math between the return and initial charges on my credit card the final cost for the dozen arrows came out to $99.99 USD or $123.20 CDN. I ordered my arrows with the 20% off code at Father’s Day. I have seen others offering discount codes on ArcheryTalk and Instagram. This is a remarkably cheap price for a dozen arrows with Killn’ Stix Ventilators at $182/dozen (from their website) and Easton Axis at $160/ dozen (via canadaarcheryonline). However after looking at the components this was not the true cost. I replaced both the inserts and the nocks. So an additional $35 dollars was spent on Easton HIT inserts and Easton X nocks. That brings the useable tally to $158.20 for the Arachnid Archery Widowmakers, so about the same as Easton Axis arrows online. *It should be noted that the Killn’ Stix Ventilators are a .001 straightness where the other 2 are .003 straightness.

The Arrow Shafts

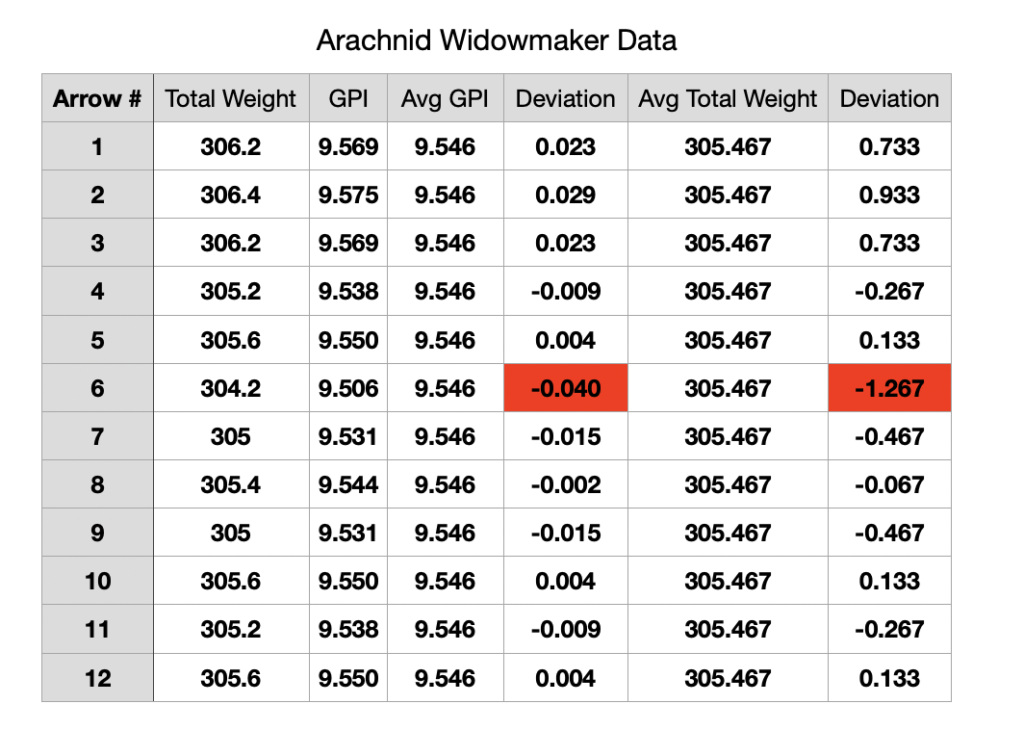

Let’s talk about the arrow shaft itself, Arachnid lists the shafts to be +/- 1 grain per dozen and I found that the shafts all met that tolerance. Next up was do the shafts meet advertised GPI, on that end they do not. The shafts are listed as 9.8 gpi, I found them to be 9.5 gpi. While this seems like a small difference, a common shaft length of 28″ would yield a build weight of 8-9 grains lighter. If you are picky about your arrow setups, and you rely on manufacturers to post accurate values for your builds this may be a big detterent.

Below is a chart showing the individual arrow weights and the average deviation.

Onto straightness, these shafts are listed at .003, industry standard is for that to be over 28″ of the shaft. Meaning the remaining 4 inches, not necessarily at one end may have higher runout. Here is a few video clips of the shafts spinning to get a feel for the runout at the ends.

Arachnid Archery Components

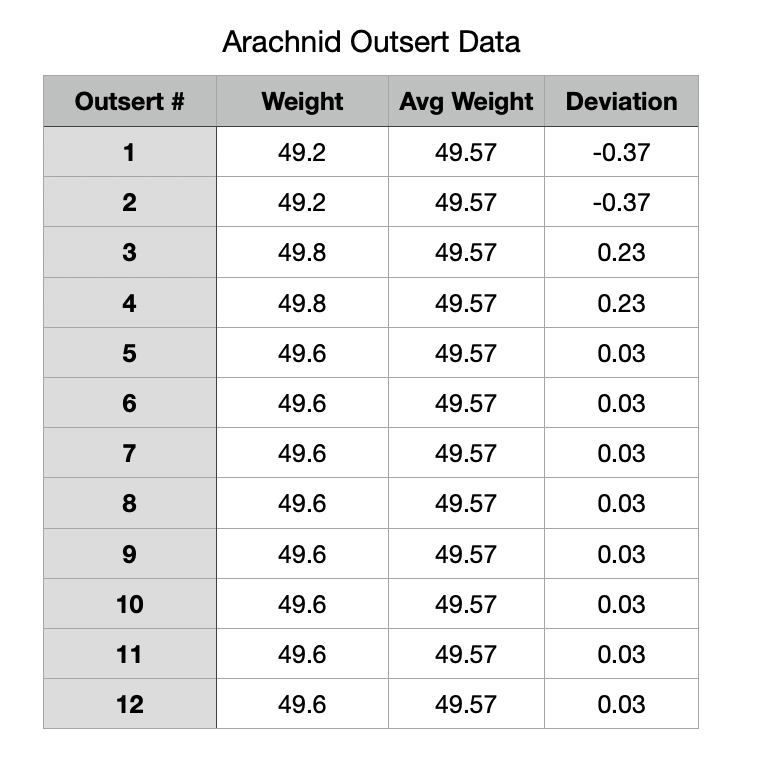

This section will be very simple, I did weigh and check tolerances on the components but I did not use them. I will start with the outserts.

Arachnid Archery .204 Outserts

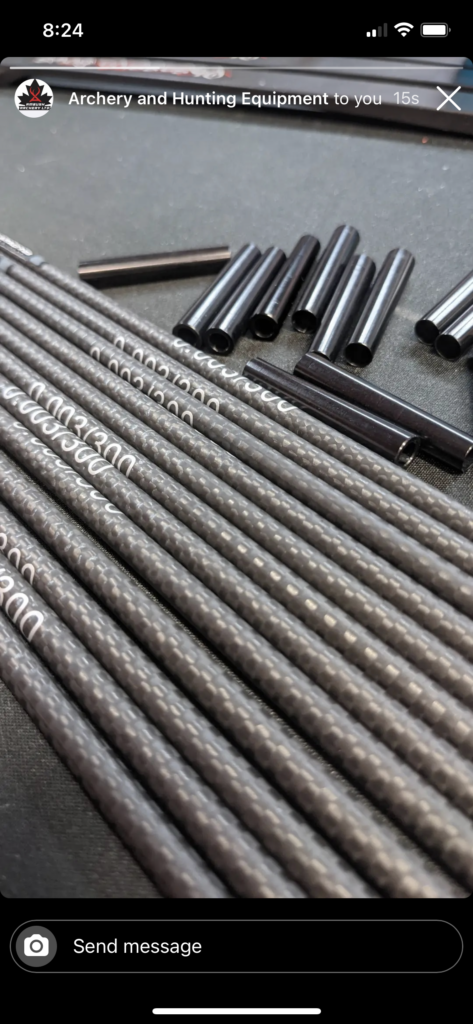

As I outlined in Part 1, I received Stainless Steel outserts with my order. The website does still show 7075 aluminium outserts and I got sent this photo from another customer showing a footer type outsert system similar to the Gold Tip idea on their Widowmakers.

Here is a chart showing the tolerances of the outserts that I received.

I did not install any of these outserts as I do not believe they will stay in and they pose a large risk of breaking a shaft on a quartering shot because of their length. The outserts only have a 1/2″ section that will be glued into the arrow. This does not provide much for glue surface and creates an extremely short lever. I also found them to be extremely loose inside the shaft itself which added to the decision to not use them. Below is a few photos showing the lengths of the outsert shafts compared to some standard diameter inserts.

Here is a video showing the loose fitment of the outsert in the shaft. This poses an issue as the insert may not glue completely true with the arrow shaft. This could result in poor broadhead spinning and flight.

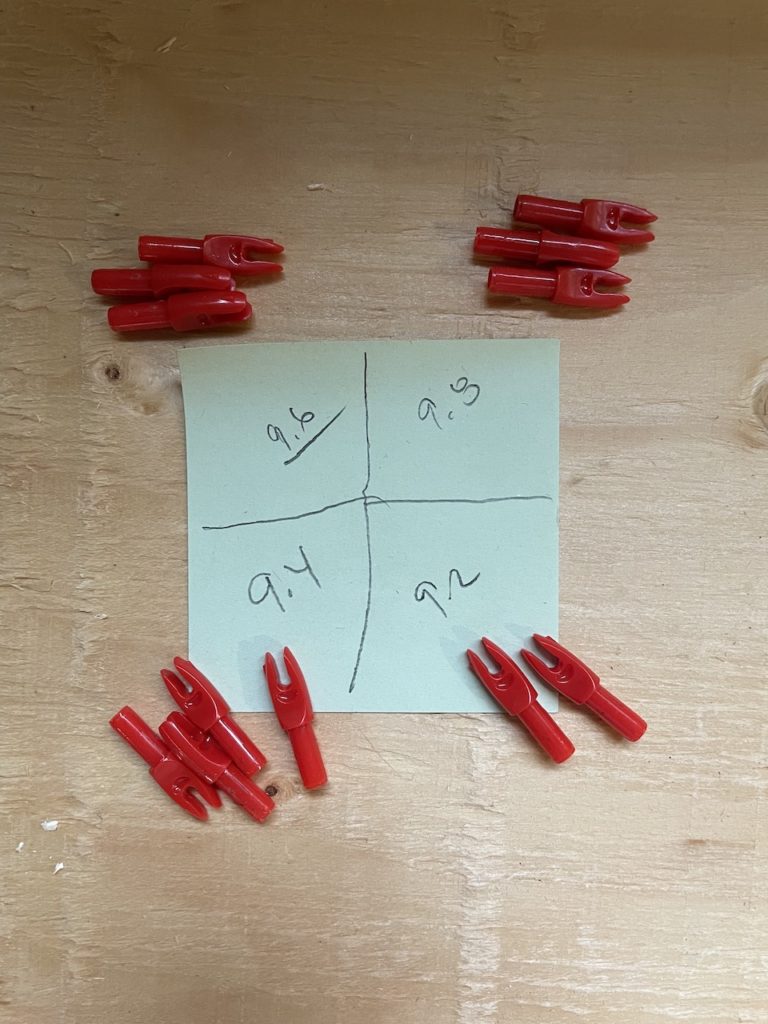

Arachnid Archery . 204 Nocks

Next up is the nocks, weight wise they were also pretty consistent as shown below.

My issue comes from the fitment of these nocks to my bow string. In this short video I show the difference between these nocks and several other brands to show the concern. In the end buying new nocks was cheaper than re-serving my string at the nocking point. As I currently do not own the supplies or tool to do so.

Whats to come….

I hope this information is valuable to you and look forward to sharing Part 3 the arrow build process and results with you soon!

-R